Shawl (detail), 1790–1825, wool, India (Cooper Hewitt, Smithsonian Design Museum)

For centuries, handwoven cloth from the Kashmir region of the Indian subcontinent has been revered for its exquisite softness and decorative surface patterns. The fleece used to make the cloth is known as pashm, meaning “soft hair” in Persian, and is usually gathered from the soft undercoat of Himalayan goats. This wool cloth is now sometimes known as “cashmere” after the old English spelling of “Kashmir,” or as “pashmina” from the word “pashm.”

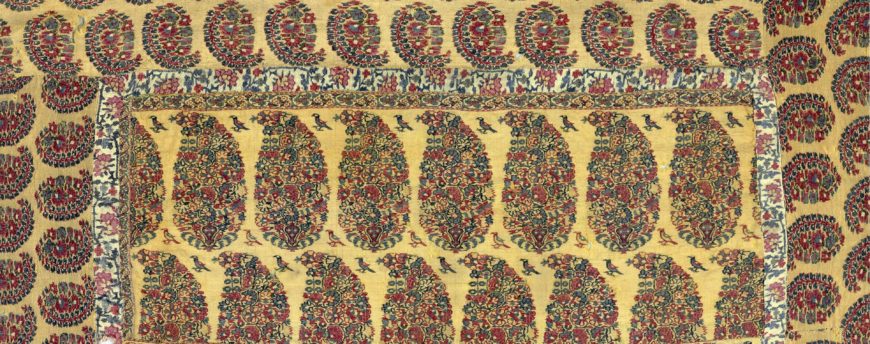

Attributed to Kashmir, detail of shawl of joined fragments, late 18th century, pashmina wool (The Metropolitan Museum of Art)

It is generally agreed that the cloth’s production had begun by the mid-fifteenth century. The industry was boosted in the sixteenth century under the patronage of emperors of the Safavid, Zand, and Qajar empires in Iran and the Mughal empire of northern India. It gained further momentum after the Mughal Emperor Akbar conquered Kashmir in 1568 and established imperial workshops for Kashmiri cloth manufacture.

From the sixteenth century through the eighteenth century, the cloth was sold on sea and overland trade routes to China, Central Asia, Russia, and the Ottoman Empire. Production of the cloth involves the efforts of numerous specialists, including goat-herders, people to sort and clean the fleece, spinners, dyers, designers, weavers, and needleworkers.

The teardrop-shaped floral motif which frequently adorns the cloth is known as a buta, meaning “flower” in Hindi-Urdu or boteh meaning “bush” or “shrub” in Persian. It has been suggested that its shape derives from representations of cypress trees in pre-Islamic Iran—the cypress tree being a symbol of eternity in Zoroastrianism (an ancient Persian religion). [1] In the Mughal period this motif was merged with depictions of flowering plants to resemble a tapered and curved flowering bush as in the shawl above.

A woman wearing a cashmere shawl, Alfred Stevens, Departing for the Promenade (Will You Go Out with Me, Fido?), 1859, oil on panel, 61.6 x 48.9 cm (Philadelphia Museum of Art)

European imitations

From the late eighteenth century, European traders working in India wore Kashmiri cloth and often gifted it to their relatives, launching a European fascination with the fabric. Although in Asia the cloth was worn by both men and women and was used to make a variety of fabrics (including clothing such as gowns, sashes, stockings, and furnishings such as curtains and coverlets), its introduction to Europe coincided with the rise of the shoulder mantle in women’s fashion. While the Persian word shaal refers to a variety of woolen fabrics, in the “West” the word (English: “shawl”; French: “châle”) came to refer specifically to the shoulder mantle.

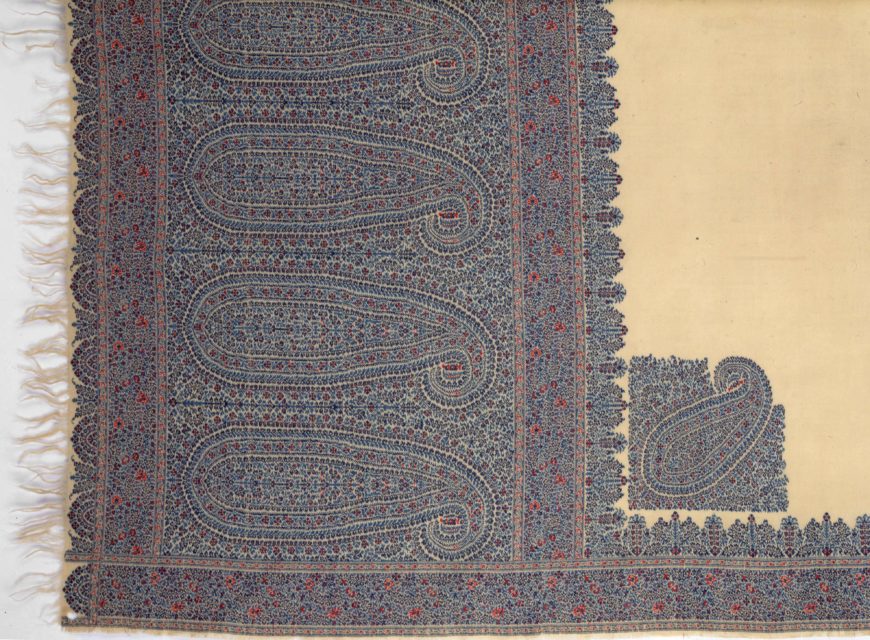

Shawl made on the draw loom, woven wool, 1825–30, Europe (The Metropolitan Museum of Art)

European manufacturers seized on this new fashion, producing imitations of Kashmiri shawls at lower prices. This was first taken up by manufacturers in cities and towns with prominent textile industries, such as Edinburgh and Norwich from the late eighteenth century and Paris, Vienna, and Moscow from the early nineteenth century. Production also began in the town of Paisley, Scotland from 1805. Thanks to local technological innovations and a focus on the mass market, Paisley’s industry became so successful that by the mid-nineteenth century its name was, for many Anglophones, synonymous with the shawls’ characteristic buta motif.

A shawl from The Metropolitan Museum is an example of a European shawl produced on the draw loom, which imitates the Kashmiri style of a plain ground lined by a border with buta motifs. In European imitations the motif became increasingly stylized, leading some historians to consider the more abstract “paisley” variation as distinct from the buta.

Wealthier Europeans still purchased shawls from India due to their authenticity and superior quality. Kashmiri shawls continued to be made from Himalayan pashm, while European ones were more commonly made from blends of cotton, silk, and coarser wool from sheep and other goat breeds—fibers that were more affordable and therefore enabled European manufacturers to undercut Kashmiri shawls on the market.

This tili shawl was woven in several different pieces and then stitched together. Shawl, 1790–1825, wool, India (Cooper Hewitt, Smithsonian Design Museum)

Changing methods and designs

Kashmiri manufacturers responded to European competition by devising new techniques that reduced production time, including tili or patched shawls, which were sewn together from several different woven pieces (meaning that several sections could be woven at once).

This amli shawl was stitched from different woven pieces and then embroidered. Detail of shawl, 19th century, wool, India (Cooper Hewitt, Smithsonian Design Museum)

It also included amli shawls, which were fully embroidered on plain wool or cotton grounds (and took considerably less time than it took to weave a shawl). Amli shawls which used cotton grounds were also more feasible when, during the early nineteenth century, there were wool shortages due to epidemics among the pashmina goats.

Shawl woven on a Jacquard loom, 1840–60, wool, probably Scottish (The Metropolitan Museum of Art)

Detail of shawl woven on a Jacquard loom, 1840–60, wool, probably Scottish (The Metropolitan Museum of Art)

From the 1810s, French shawl manufacturers used a new loom known as the Jacquard loom, which automated much of the weaving process using a system of perforated cards. The Jacquard loom enabled French manufacturers to quickly weave more complex and detailed patterns including motifs such as flora, fauna, humans, and architecture.

The Jacquard loom was also adopted by other European shawl manufacturers including those in Paisley, which is the likely provenance of this square shawl from the 1860s. Its white center is bordered by a pattern with long, flowing lines including paisley motifs.

Decline of the shawl industries

In Europe, mass-production reduced the shawl’s exclusivity and therefore its social prestige. Women’s fashions changed and, from the 1860s on, shawls were often repurposed into other garments such as capes, cloaks, dolmans, mantles, and stoles, such as one in The Metropolitan Museum of Art.

Cloak made in the United States between 1885–89 from an embroidered wool and silk Indian shawl (The Metropolitan Museum of Art)

Like the European shawl industry, the Kashmiri industry experienced a downturn from the 1870s. This was partly due to the decline of the shawl fashion in Europe and the Franco-Prussian War (1870–71), which closed off the European market. However, some historians have highlighted the role which European imperialism first played in restructuring trade in Asia and suppressing Kashmir’s historical markets. [2] Combined, these factors led to mass unemployment among Kashmir’s artisans, many of whom subsequently perished in the severe famine between 1877–79.

The Kashmiri shawl industry continues today, but suffers from a new threat: climate change. Due to warmer temperatures and shorter winters in the Himalayas, the pashmina goats do not produce the same quantity or quality of pashm. [3] The crisis is a strong reminder of the degree to which historic art forms such as cashmere are reliant on site-specific climate and natural resources.

Notes:

[1] Ben Skarratt, Scarlett Mansfield, and Christopher McKenna, “From India to Europe: The Production of the Kashmir Shawl and the Spread of the Paisley Motif,” Global History of Capitalism Project, University of Oxford (August 2018)

[2] Michele Maskiell, “Consuming Kashmir: Shawls and Empires, 1500–2000,” Journal of World History 13, No. 1 (Spring 2002): pp. 48-52

[3] Andrew Newey, “Cashmere Country: The Perils of Making the World’s Finest Fabric,” The Guardian (10 January 2020)

Additional resources:

Mary M. Dusenbury, Flowers, Dragons, and Pine Trees: Asian Textiles in the Spencer Museum of Art (Manchester, VT: Hudson Hills Press, 2004).

John Irwin, The Kashmir Shawl (London: Her Majesty’s Stationery Office, 1973).

Chitralekha Zutshi, “‘Designed for eternity’: Kashmiri Shawls, Empire, and Cultures of Production and Consumption in Mid-Victorian Britain,” The Journal of British Studies 48, no. 2 (April 2009), pp. 420–40.